Whether you're a novice or an experienced user, encountering issues with your Creality Falcon 2 laser engraver and cutter can be frustrating. To maximize your productivity and minimize downtime, it's crucial to understand how to troubleshoot common problems effectively.

In this article, we'll explore some frequent issues users face with the Creality Falcon 2 and provide practical solutions to resolve them.

Creality Falcon 2 Common Setup Problems and Solutions

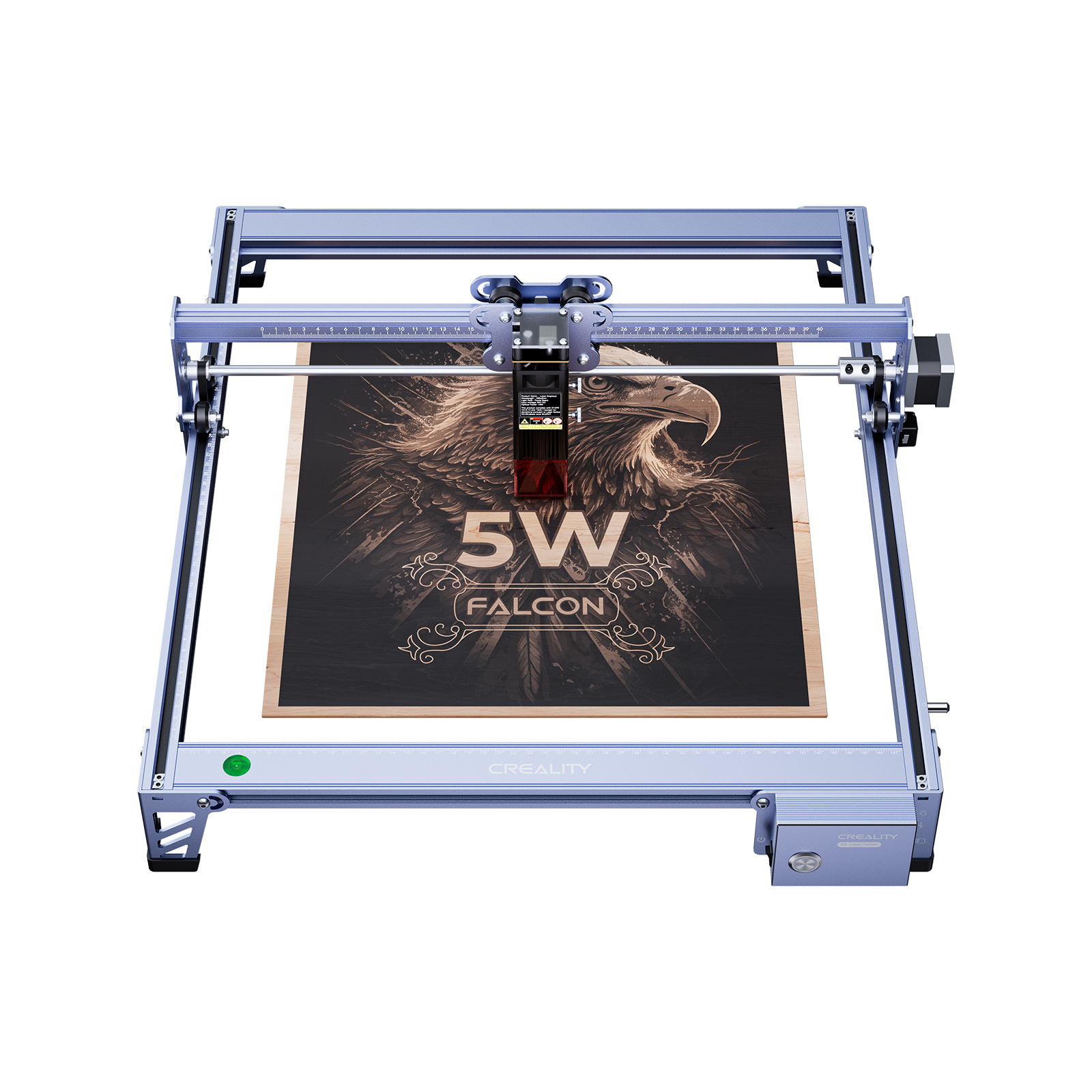

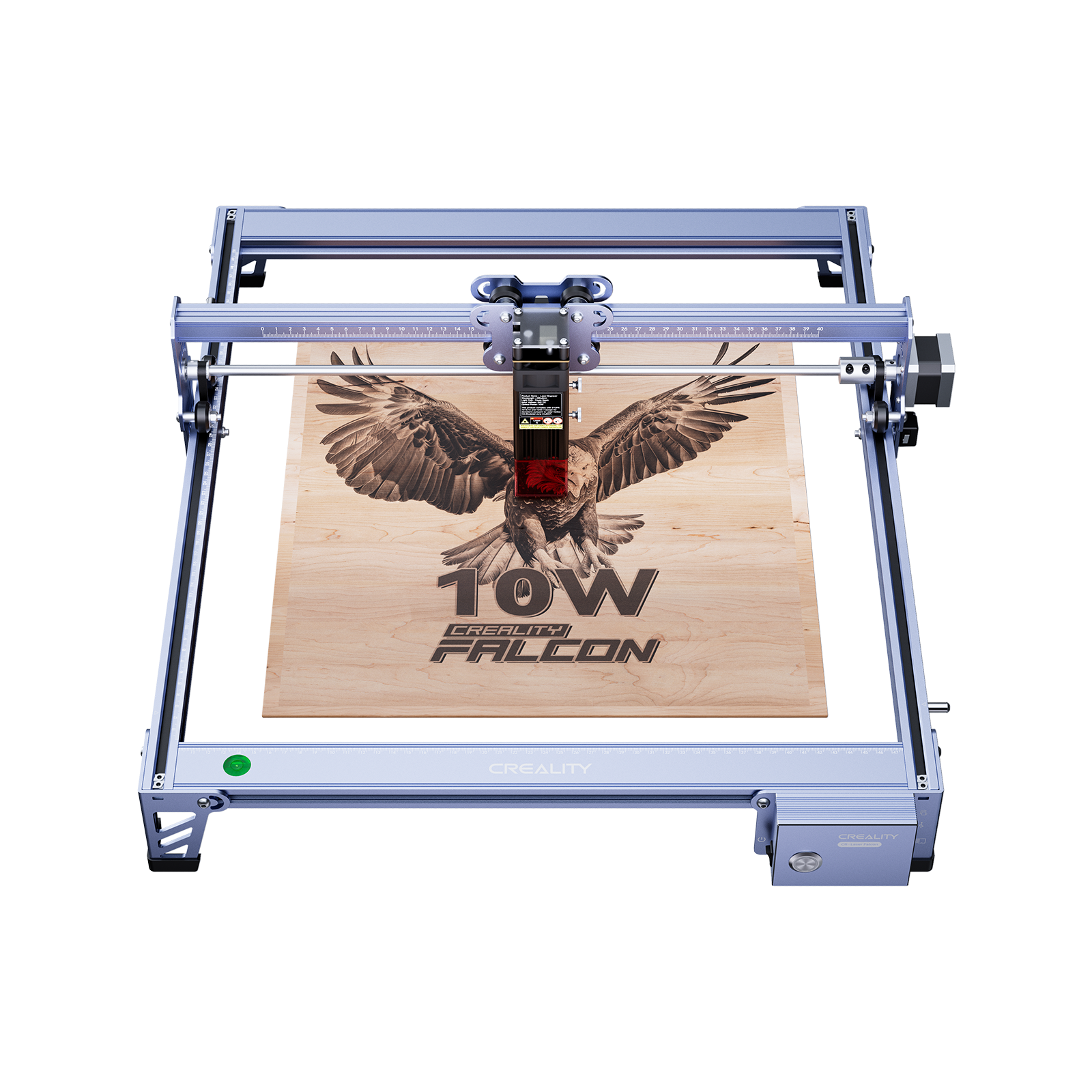

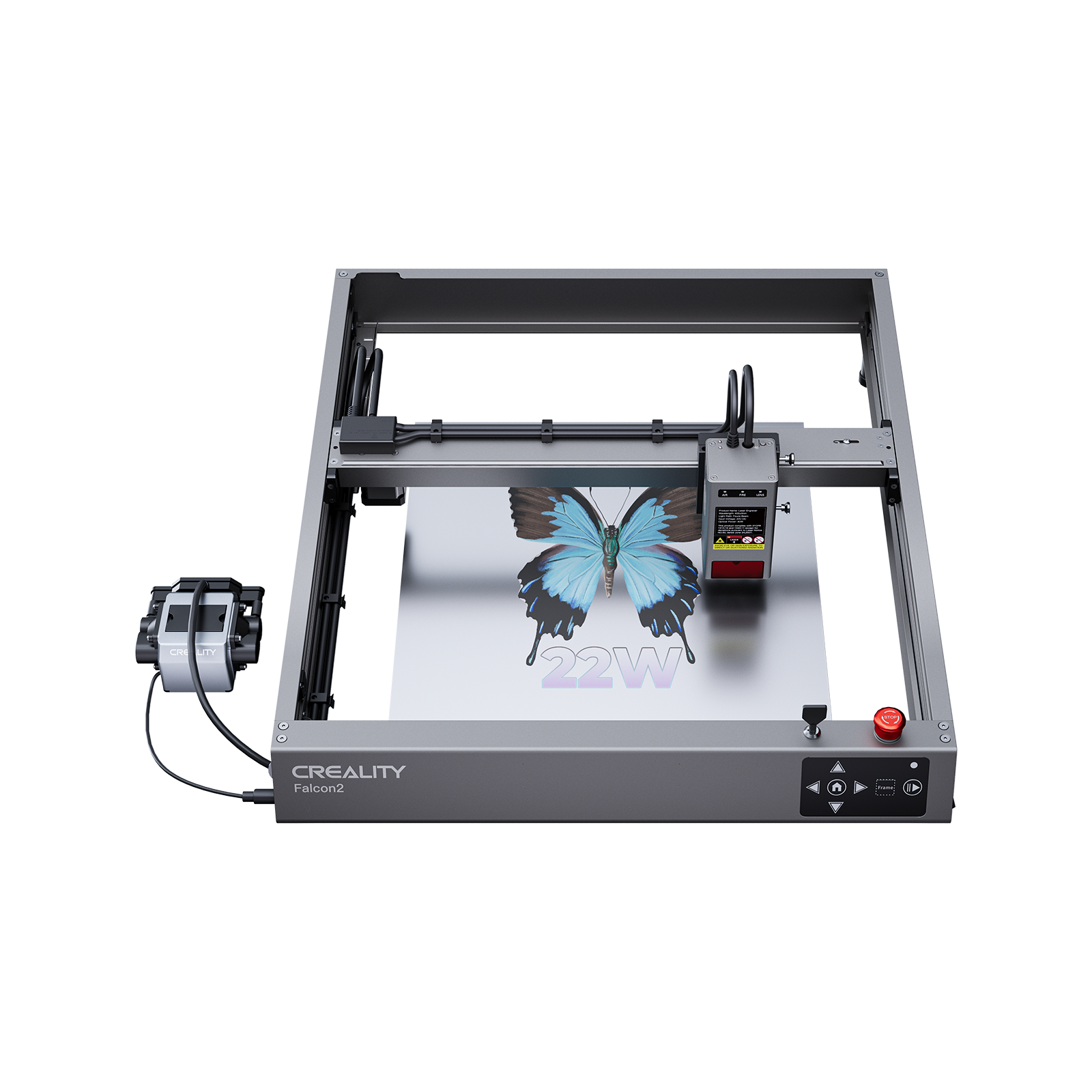

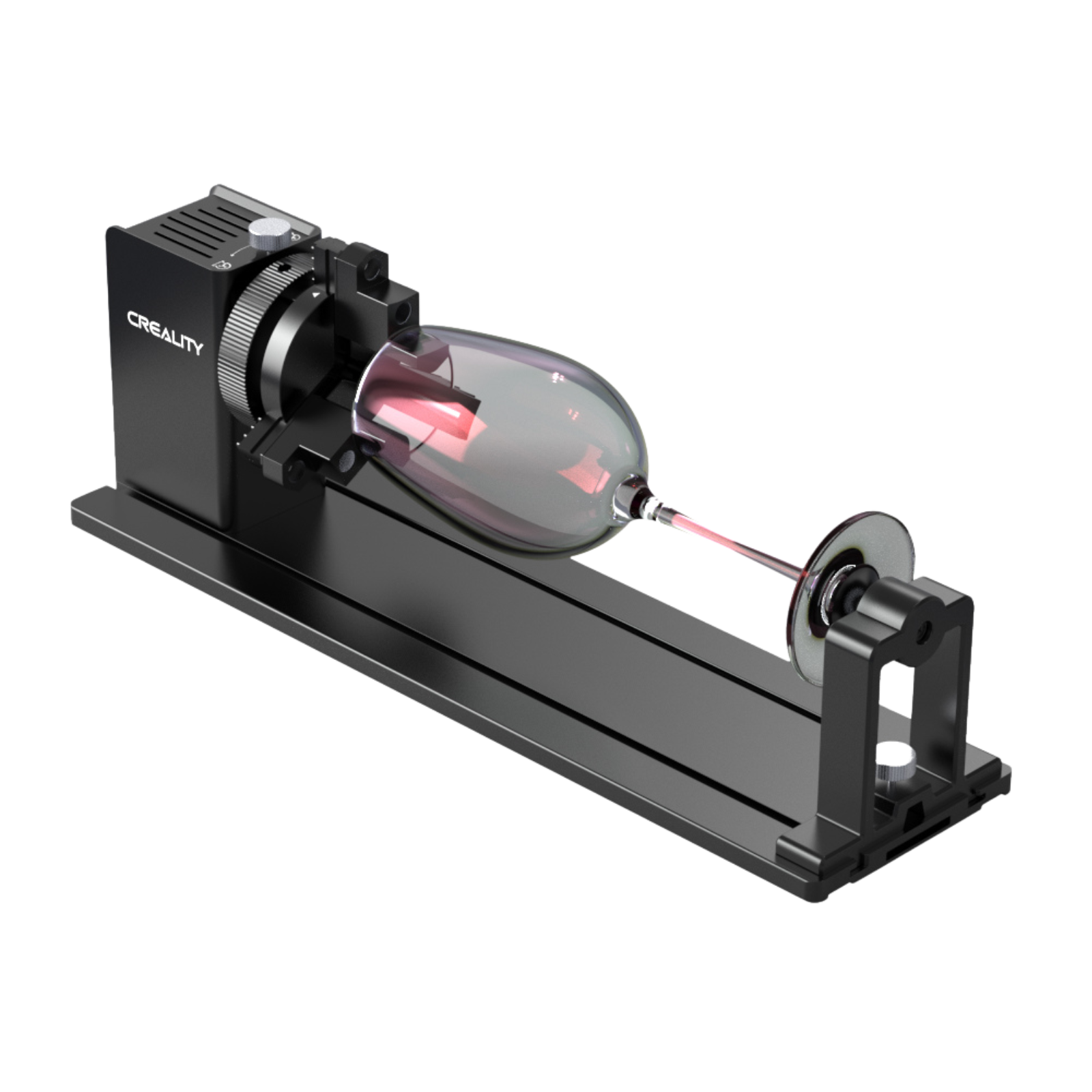

About the Creality Falcon 2 Laser Cutter

1. What is the size of the engraving area?

The engraving area measures 400mm x 415mm.

2. What is the type of laser source?

The Creality Falcon 2 laser cutter uses a semiconductor laser unit.

3. What happens if the machine powers off during operation?

The machine will stop working. When powered back on, it will need to be reinitialized.

4. Why is the engraving effect so shallow?

A shallow engraving effect often results from unclear imported images. Ensure proper focusing before engraving, and adjust the power and speed settings appropriately.

5. Why does the engraved effect differ from the original image?

Check that all screws are tight and that the belt isn’t too loose or too tight. The belt is correctly tensioned if the laser module can slide slowly on the X-axis profile perpendicular to the desktop by gravity, with no empty sliding in any pulley.

6. What should I do if the engraving effect is inconsistent in depth?

Ensure the material to be engraved is flat. Use the gradienter on the machine to verify that it is horizontal and properly adjusted according to the user manual.

7. How do you focus the laser?

Place the multi-level fixed focus bar between the laser module and the material. Make the bottom of the laser module contact the corresponding surface of the focus bar, then lock it using the two hand screws on the right. For example, when engraving or cutting a 2mm basswood or similar material.

8. Will the laser damage the workbench?

The laser may penetrate the material and damage the workbench, especially during cutting. To prevent this, place non-penetrable objects such as stainless steel or aluminum alloy plates underneath the workpiece.

9. Why can't the machine read the G-code file or reads the wrong file?

1. Ensure that the TF card is properly inserted. The machine defaults to reading the latest engraving file (.gcode/.gc) in the root directory of the TF card. It is advisable to delete other engraving files in the root directory.

2. The G-code file should be generated by LightBurn. If the file is generated with the .gc extension, manually change the suffix to .gcode.

10. What should I do if the buzzer makes a rapid alarm sound?

If the machine turns on its side or moves during preview or engraving mode, the laser will turn off, the motor will stop, the indicator light will flash, and the buzzer will sound. Move the machine back to its original position and press the “Frame” or “Start/Pause” button to continue after clearing the abnormality.

11. What should I do if the machine cannot be turned on?

1. Ensure the power plug is properly plugged in.

2. Verify the power outlet is functioning correctly.

3. Check that the power switch, emergency stop switch, and child lock are turned on.

12. Do I have to wear goggles?

The Creality Falcon 2 laser cutter features a shading and eye protection design and integrates the MEMS attitude sensor, which stops the laser module if the machine turns on its side. Despite these features, it is still recommended to wear goggles during operation.

13. The buzzer suddenly emits a beep and then stops working. How should I deal with it?

The machine has four limit switches. If the laser module exceeds the engraving area during operation, the buzzer will beep, and the machine will stop. Adjust the position of the laser module and check the size of the graphics.

14. What happens if the belt is too loose or too tight?

Improper belt tension causes deformed and dislocated engraved graphics, such as a circle changing into an ellipse.

About Engraving or Cutting with the Creality Falcon 2 Laser Cutter

1. What materials can I engrave or cut?

Engraving: Paper, Wood, Bamboo, Leather, Textile, Acrylic, Painted Metal, Plastic, etc.

Cutting: Paper, Wood, Bamboo, Cloth, Leather, Fabric, Acrylic, Plastic, etc.

2. Can I engrave on curved materials?

Yes, but the curvature should not be too severe, as it may cause slight deformation in the engraving effect.

3. Can I engrave on reflective or transparent materials, like ceramics or glass?

Yes, but you need to apply an anti-reflective coating on the surface of the material to ensure a good engraving effect and to prevent reflected light from damaging the laser module.

4. Why do I get different engraving effects on the same material in different colors using the same G-code file?

Materials of different colors have varying optical properties, which affect how they absorb and reflect laser energy. You can achieve the desired effect by adjusting the parameters accordingly.

5. How can I deal with smoked traces on the surface of the material?

Reduce the laser power appropriately and use the air assist from Creality to minimize smoke marks.

6. Why can't I cut through the material?

1. Ensure the machine and material are parallel to the workbench.

2. Make sure the protective lens of the laser module is clean.

3. Refer to the user manual for correct focusing.

4. Follow the recommended parameters in the TF card.

5. Gradually increase the number of passes or reduce the cutting speed as needed.

7. Should I use the air assist?

The powerful and stable airflow from the air assist can effectively blow away smoke and dust during cutting, protecting the laser module's lens and ensuring stable laser energy. It also helps in quickly reducing the surface temperature and keeping material surfaces clean, resulting in smoother cutting edges. It is recommended to use weak airflow when engraving and strong airflow when cutting, depending on the specific material.

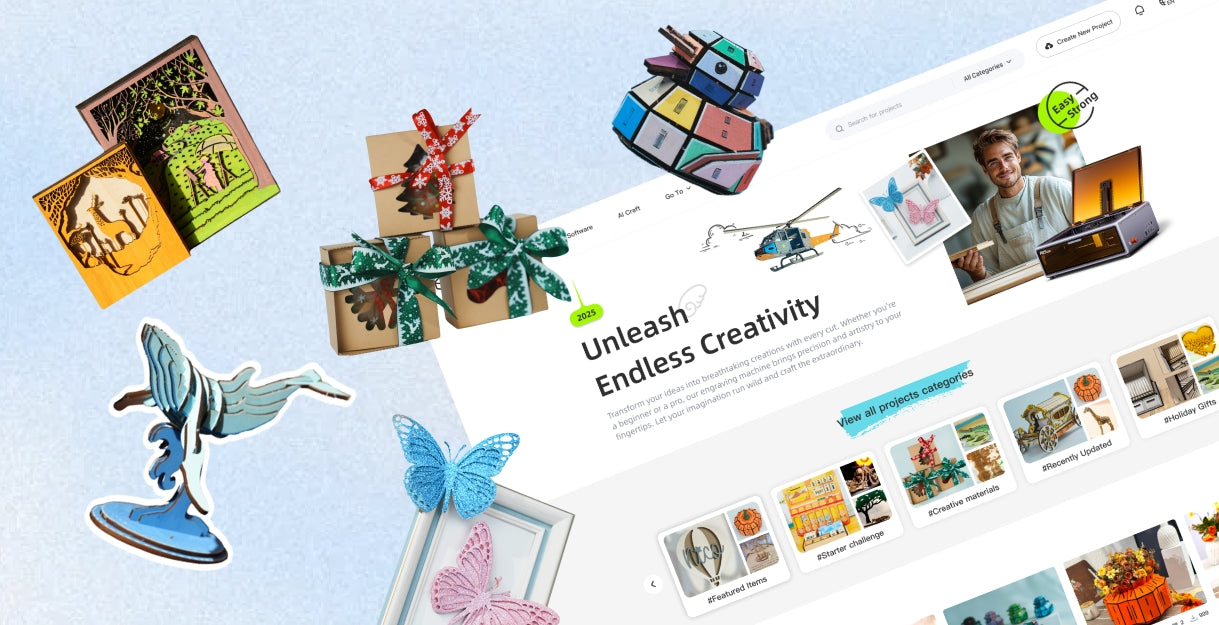

About Software

1. What software can I use for the Creality Falcon 2 Laser Cutter?

LaserGRBL: Free

LightBurn: Paid (30-day free trial available)

2. Where can I download the software?

3. What file formats can I import into the software?

LaserGRBL: bmp, png, jpg, gif, svg

LightBurn: bmp, png, jpg, jpeg, gif, tif, tiff, tga, ai, pdf, sc, dxf, hpgl, plt, rd, svg

4. Where can I find tutorials?

The TF card that comes with the machine includes basic tutorials. For more detailed tutorials:

5. What should I do if the COM port corresponding to the engraving machine is not identified in a Windows 7 system?

Unzip the driver package and manually install the driver via the Device Manager.

6. What should I do if the software does not respond or cannot connect during online operation?

1. Ensure the Type-C data cable supports communication and that the end connected to the computer is a USB-A interface.

2. Make sure you have successfully imported the Creality Falcon2.lbdev file.

3. Verify that the machine's COM port is not occupied.

4. If the issue persists, record a video of the problem and provide your system information and software version to customer support.

Creality Falcon 2 Troubleshooting

Error Code Table 1. Always ensure the machine is placed in a well-ventilated environment, free from flammable materials, heat sources, and volatile solvents.| ERROR CODE | PROBLEM | TROUBLESHOOTING |

|---|---|---|

| ERROR:01 | The angle data is abnormal and it has stopped working. | Please check whether the workbench is shaking, the screws are locked tightly and the frame of the machine is firm. |

| ERROR:02 | There is no G-Code file in the root directory of the TF card. | Please check whether the suffix of the file in the TF card is \".gcode\/.gc\/.nc\", and ensure the file is saved in the root directory. |

| ERROR:04 | No airflow is detected and the machine has stopped working. | Please check whether the air pump is connected to the machine, check whether the knob switch on the left side of the machine is adjusted to the maximum, and check whether the silicone air tube above the laser module is inserted and there is no kinks in the tube. In the Falcon Machine Settings you can change: $153 to 0 to cancel the alarm function (it is recommended to set it according to the actual situation). |

| ERROR:05 | A flame has been detected and the machine has stopped working. | Please press the Reset button if the material is not burning, and the FIRE light will turn orange, indicating that there is a risk of fire. You can press the start button to continue working and after restarting the machine, the FIRE light will be green. Refer to “Laser Module Alarm Functions.pdf” for more information. In the Falcon Machine Settings you can change: $154 to 0 to cancel the alarm function (it is recommended to set it according to the actual situation). |

| ERROR:06 | Lens contamination is detected and the machine has stopped working. | Please press the Reset button and the LENS light will turn orange. You can press the start button to continue working and the lens needs to be cleaned when powered off. The LENS will still keep red light flashing when power on. You need to press the reset button again to confirm that the lens is clean and the LENS light will be green. Refer to “Laser Module Alarm Functions.pdf” for more information. In the Falcon Machine Settings you can change: $155 to 0 to cancel the alarm function (it is recommended to set it according to the actual situation). |

| ERROR:07 | The temperature of the laser module is high and it has stopped working. | You can press the Reset button and then press the Start button to continue the current work. It is recommended to clean the laser module when powered off and wait for the laser module to cool down to a suitable temperature before working. In the Falcon Machine Settings you can change: $158 to 0 to cancel the alarm function (it is recommended to enable the alarm function). |

| ERROR:08 | The air pressure sensor of the laser module is not performing correctly. | It is recommended to restart the machine to see if it is solved. If the error persists, please contact the after-sales service for relevant technical support. |

| ERROR:09 | The flame sensor of the laser module is not performing correctly. | It is recommended to restart the machine to see if it is solved. If the error persists, please contact the after-sales service for relevant technical support. |

| ERROR:10 | The lens sensor of the laser module is not performing correctly. | It is recommended to restart the machine to see if it is solved. If the error persists, please contact the after-sales service for relevant technical support. |

| ERROR:11 | The laser module does not have an LD temperature sensor. | It is recommended to restart the machine to see if it is solved. If the error persists, please contact the after-sales service for relevant technical support. |

| ERROR:12 | Laser module LD sensor short circuit. | It is recommended to restart the machine to see if it is solved. If the error persists, please contact the after-sales service for relevant technical support. |

| ERROR:13 | The CPU temperature of the laser module is too high. | It is recommended to clean the laser module after power off and wait for the laser module to cool to the appropriate temperature before working. |

| ERROR:14 | The temperature of host CPU is too high. | Please check whether the ambient temperature is too high. It is recommended to wait for the host to cool down to a suitable temperature before working. |

| ERROR:24 | The machine is in an unsealed state. | Please close the protective cover and drawer, and then press the start button of the device to continue working. |

| ERROR:25 | The air pump is not performing normally. | Please contact the after-sales service for relevant technical support. |

Notes:

1. Always ensure the machine is placed in a well-ventilated environment, free from flammable materials, heat sources, and volatile solvents.

2. Only use the included power cords and regularly clean the machine to maintain optimal performance. Always connect the silicone tube on the laser module to minimize lens contamination.

3. Avoid operating the machine in humid conditions or during thunderstorms, and never touch moving parts, the laser module, or electronic areas when the machine is powered on.

4. Wear protective goggles during operation, maintain proper ventilation, never leave the machine unattended while running, and keep fire extinguishers readily available. Children under 10 should be supervised by an adult.