Wood is one of the most popular, accessible, and environmentally friendly resources on earth, utilized across various fields such as household activities, industry, and construction. Numerous technologies and methods exist for wood processing, each differing in technology, cost, and product quality. Among these, laser cutting is noted for its precision and high-quality results.

From understanding how laser cutting works to selecting the best machine, we've got you covered with insights, tips, and creative project ideas.

Part 1: How Laser Cutting and Engraving Wood Works?

Laser Engraving Wood

Laser engraving involves using a focused laser beam to etch the surface of the wood. By adjusting the laser’s intensity and speed, you can create intricate designs, textures, and detailed artwork. The results depend on the wood type, laser settings, and design complexity.

The automated laser head and its smaller spot size allow for more detailed engravings compared to traditional hand carving or wood burning. This method also significantly speeds up the engraving process.

As the laser burns the wood’s top layer, the engraved area typically displays a darker, burnt appearance. You can enhance this contrast by increasing the laser power. Woods with higher resin content naturally result in darker engraving shades.

Laser Cutting Wood

Laser cutting utilizes a high-powered laser to precisely cut through wood. The process involves vaporizing the material along the cut path, leaving clean edges. This method is ideal for creating detailed shapes and components, suitable for both artistic and industrial applications.

Unlike traditional hand tools, which are manually controlled and time-consuming, or power tools that may struggle with thin or delicate wood, laser cutters offer faster and more efficient cutting. They provide clean, accurate cuts that don't require additional finishing.

The kerf width of the laser beam ranges from 0.08 to 1 mm, ensuring minimal material wastage and precise fitting of assembly parts.

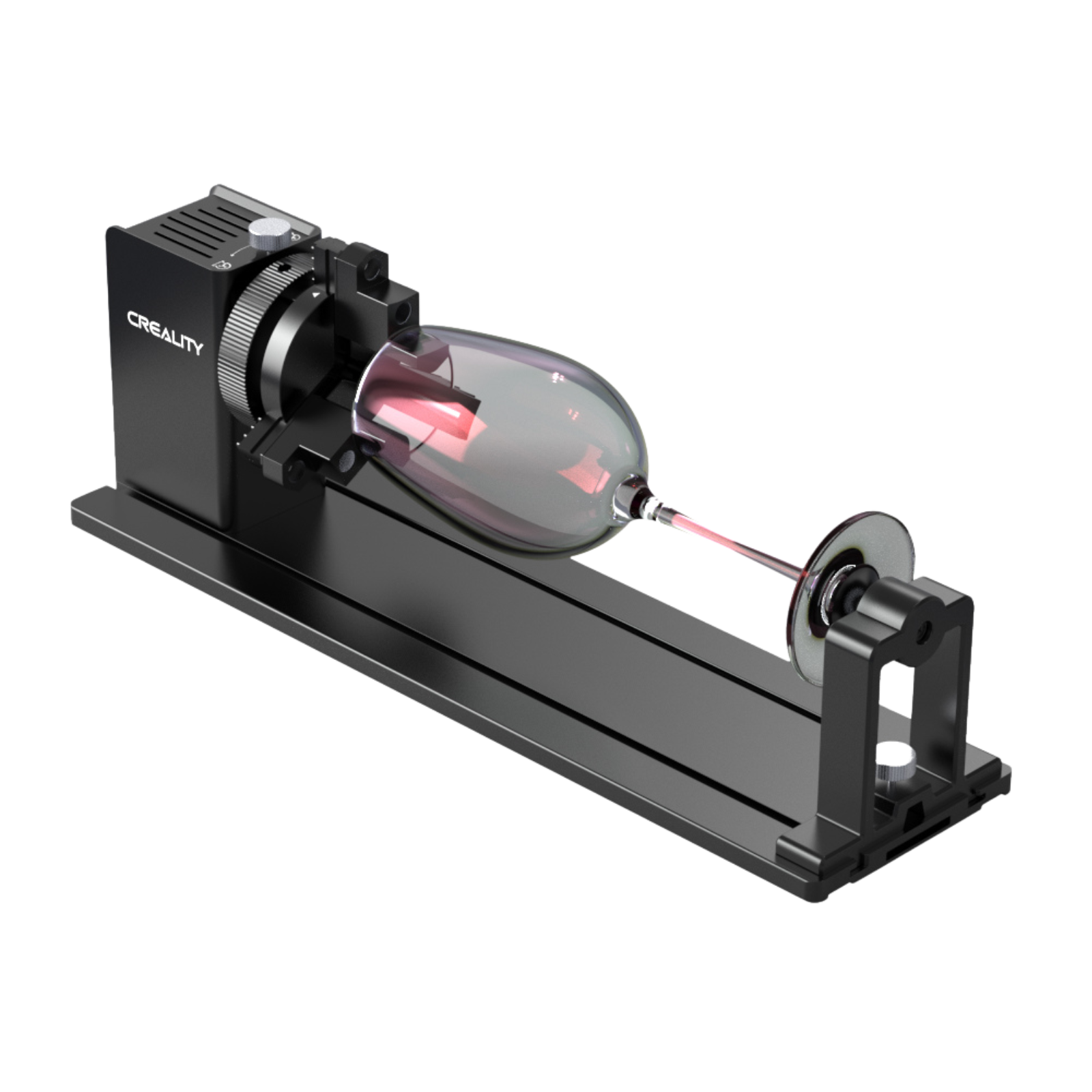

Part 2: The Best Wood Laser Cutter

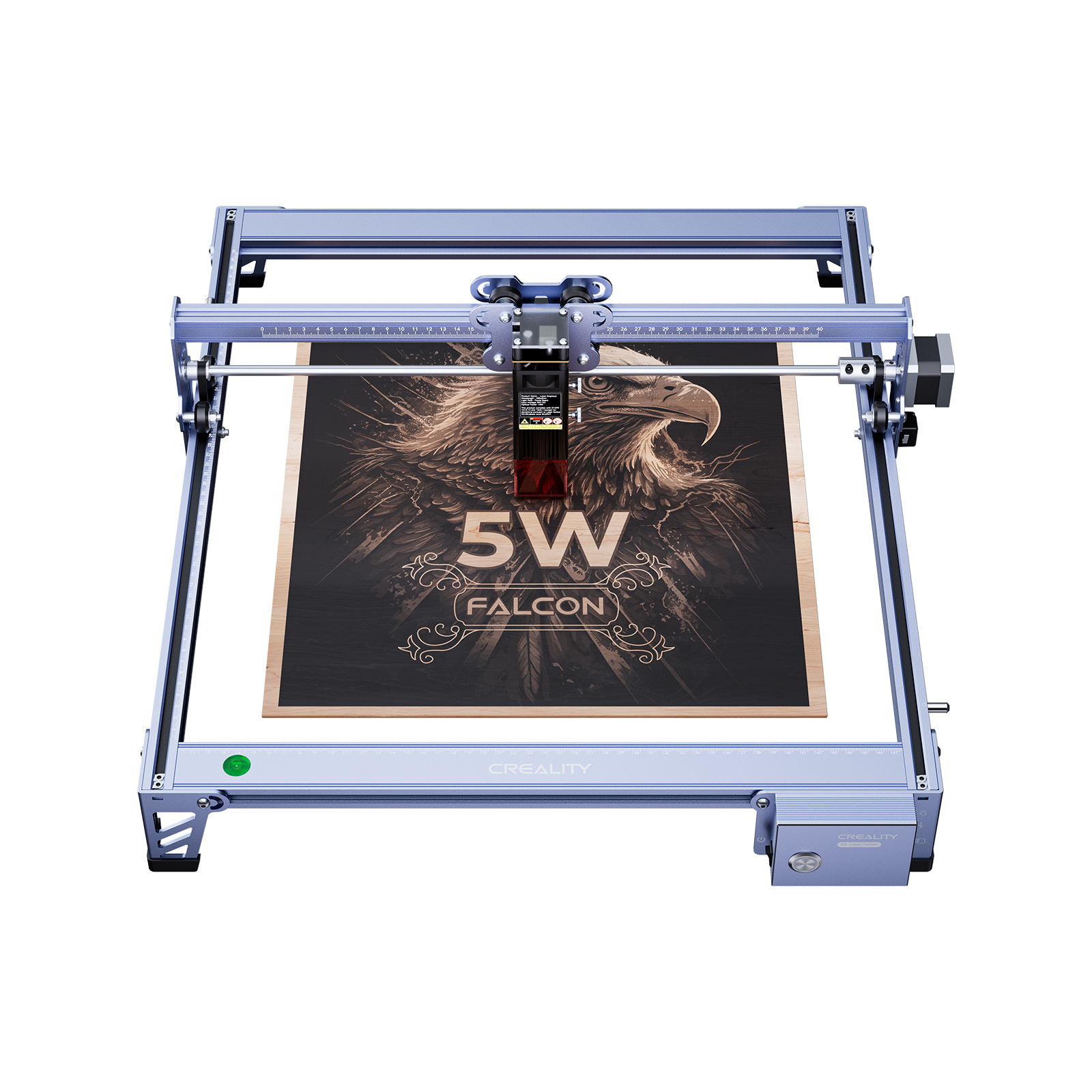

Falcon 2 Pro: Best Wood Laser Cutter for Beginners

- World’s most powerful (60W) Enclosed Diode laser cutter

- FDA Class 1 laser safe product

- MCutting 20mm basswood board in one-pass

- Large working area of 15.75*16.34 inches (400*415mm)

- Efficiently dissipates heat and smoke

- High-efficiency Batch Processing

How to Choose the Right Wood Laser Cutter?

Selecting the ideal wood laser cutter involves evaluating key aspects such as safety, precision, efficiency, and versatility. Key considerations include:

- Safety and Visibility: Look for FDA Class 1 safety certification which ensures user protection while allowing full visibility of the cutting process.

- Technology and Precision: Opt for machines equipped with visual assistance technologies for precise positioning and alignment.

- Design and Space: A 360° visual design enhances usability and aesthetics.

- Efficiency: High-efficiency batch processing capabilities maximize productivity and profitability.

- Maintenance: Features like drawer designs and fence-type protection strips facilitate easy maintenance and heat dissipation

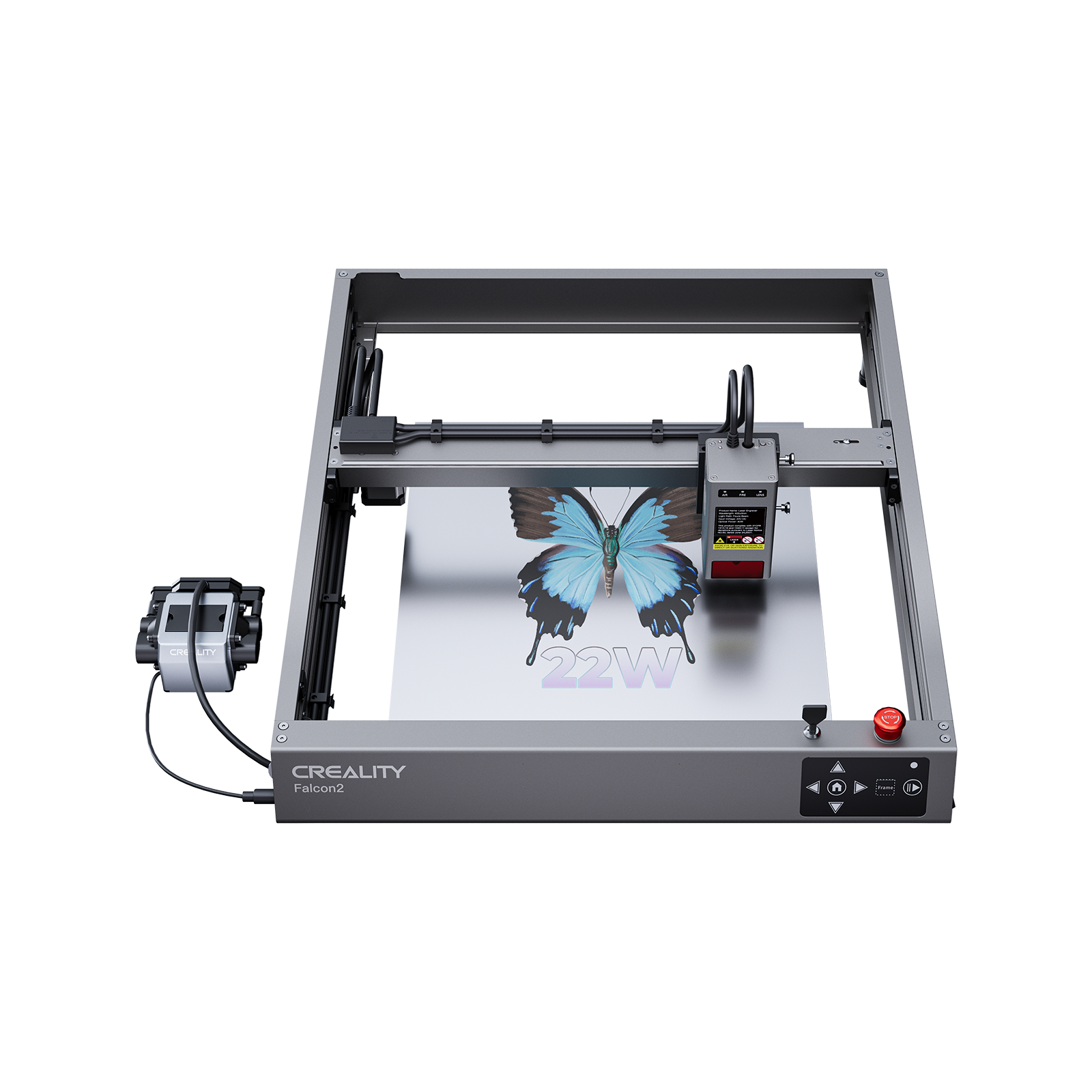

Why the Falcon2 Pro Enclosed Laser Engraver and Cutter is the Best Choice?

The Falcon2 Pro 22W/40W/60W Enclosed Laser Engraver and Cutter stands out in each of these areas. It offers top-tier safety with FDA Class 1 certification, multiple security monitoring systems, and features like lid-open safety stops to prevent laser leakage. Its Pilot Technology and built-in top camera provide precise positioning, ensuring detailed and accurate cuts.The 360° visual design combines aesthetics with functionality, allowing full visibility during operation. Efficiency is maximized through high-efficiency batch processing, making projects profitable and timely. The drawer design aids in keeping your workspace organized, while the fence-type protection strip ensures effective heat and smoke dissipation.

Compatible with both 22W, 40W,and 60W laser modules, it delivers powerful cutting capabilities, ideal for various wood projects, solidifying its position as the best choice for wood laser cutting.

Part 3: What's the Best Wood for Laser Cutting?

Wood laser cutters have diverse applications, including toys, souvenirs, frames, furniture, and chandeliers. Choosing the right material for your workpiece is crucial. Here are suitable wood types for laser cutting:

- Softwood: Requires low laser power and short processing time, ideal for balsa, poplar, and corkwood. Engravings are less contrasting due to their light color.

- Hardwood: Needs more powerful lasers and time. Oak and cherry offer bright, high-contrast engravings.

- Veneer: Homogeneous structure makes it great for engraving.

- Plywood: A composite material of three glued layers. Use light-colored glue for better results.

- MDF, Particleboard: Smooth and homogeneous, easy and quick to cut but results in dark edges.

Coniferous woods like larch and spruce are not recommended, especially for beginners, due to their complex and heterogeneous structure, requiring precise settings that may not be easily transferable between different types.

Recommended Woods for Falcon Laser Engravers

Laser engravers generally support most types of wood. These wood types are a must-try:

Unfinished Wood

It’s known for its light brown shade and straight, even grain.

Brazilian Rosewood

Features a light-brownish color with a subtly wavy grain, suitable for both cutting and detailed engraving.

Basswood

A softwood that is easy to cut, available in a light brown hue, perfect for fine and detailed work.

Walnut Plywood

Its pale yellow or white color produces dark brown engravings, offering high contrast for clear, visible designs.

Each wood type reacts differently to laser cutting and requires specific settings for optimal results.

Read more about: Creality Falcon 2 Laser Engraving & Cutting Parameter Settings

Part 4: Cool Laser Cutting Wood Ideas

With a laser wood cutting machine, you can create a variety of objects, from simple trinkets to unique interior items. If you're just starting in this field and need inspiration, here are some amazing ideas to get you started.

- Custom Ornaments and Decorations: ersonalized Christmas ornaments or intricate wall hangings make excellent gifts and home decor.

- Toys and Models: From dollhouses to mechanical puzzles, the precision of laser cutting ensures accurate and safe pieces.

- Jewelry: Lightweight and customizable, wooden jewelry like earrings, necklaces, and bracelets can be crafted with intricate designs, offering unique and eco-friendly accessories.

- Signage: Custom signage for businesses, events, or home can be crafted with intricate detailing, offering a professional and stylish look.

- Woodburning: By adjusting the laser strength, you can achieve clear images with varying shades, perfect for creating wooden paintings of landscapes, family pictures, and portraits. This technique is also ideal for crafting plaques, signs, and more.

- Mobile Phone Cases: Purchase blank cases for specific phone models online, then use a laser machine to engrave your favorite images or words. This is an excellent business idea, as personalized cases are always in demand.

- Engraving Wooden Key Chains: This is a simple project requiring minimal materials and space. The finished products can be sold or gifted to friends and family, making it both a fun and profitable endeavor.

FAQs about Laser Cutting Wood

Can a laser engraver cut wood?

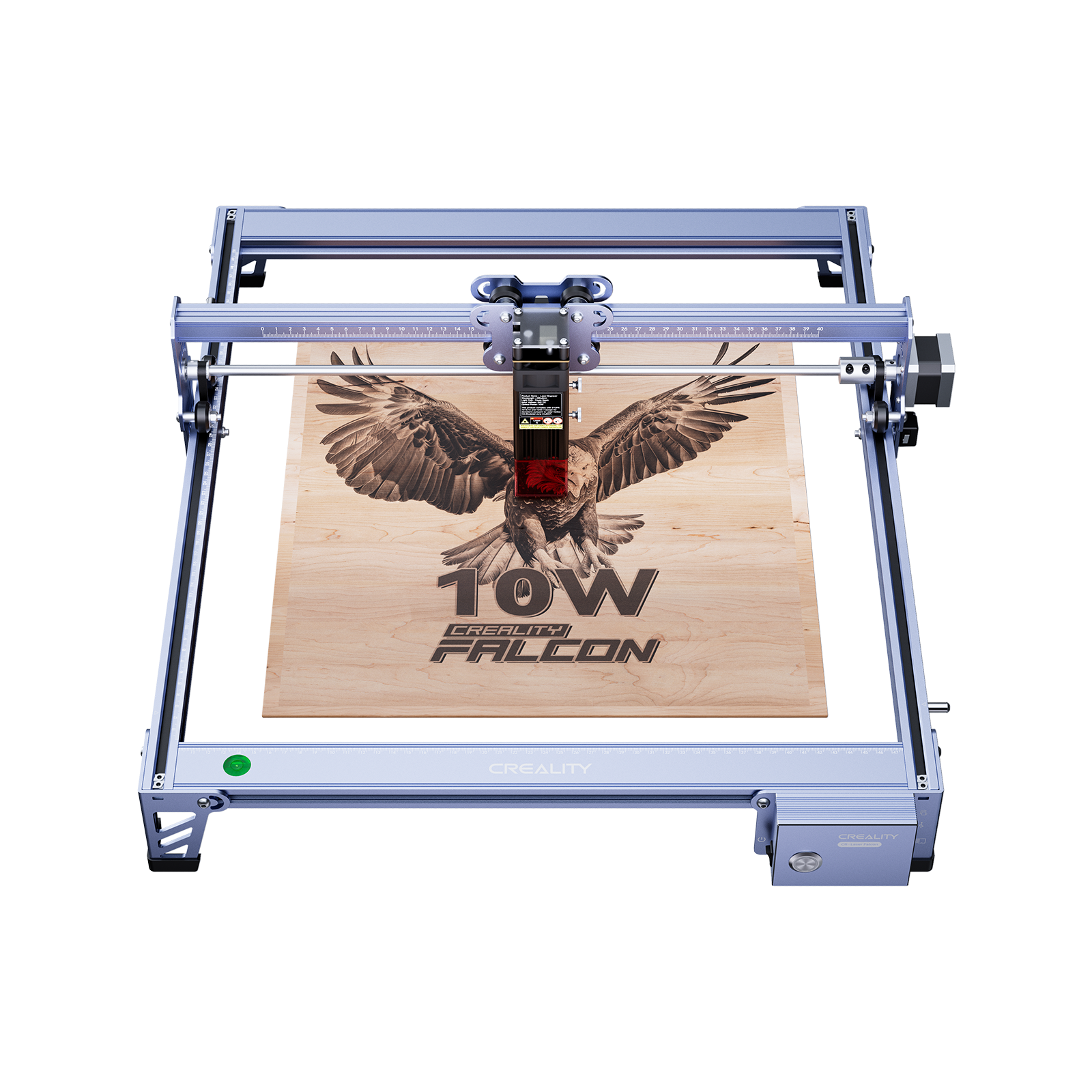

Yes, most laser engravers can handle both cutting and engraving tasks effectively. For instance, the Creality Falcon 2 40WFalcon 2 Pro laser cutter is a diode laser engraver capable of cutting wood.

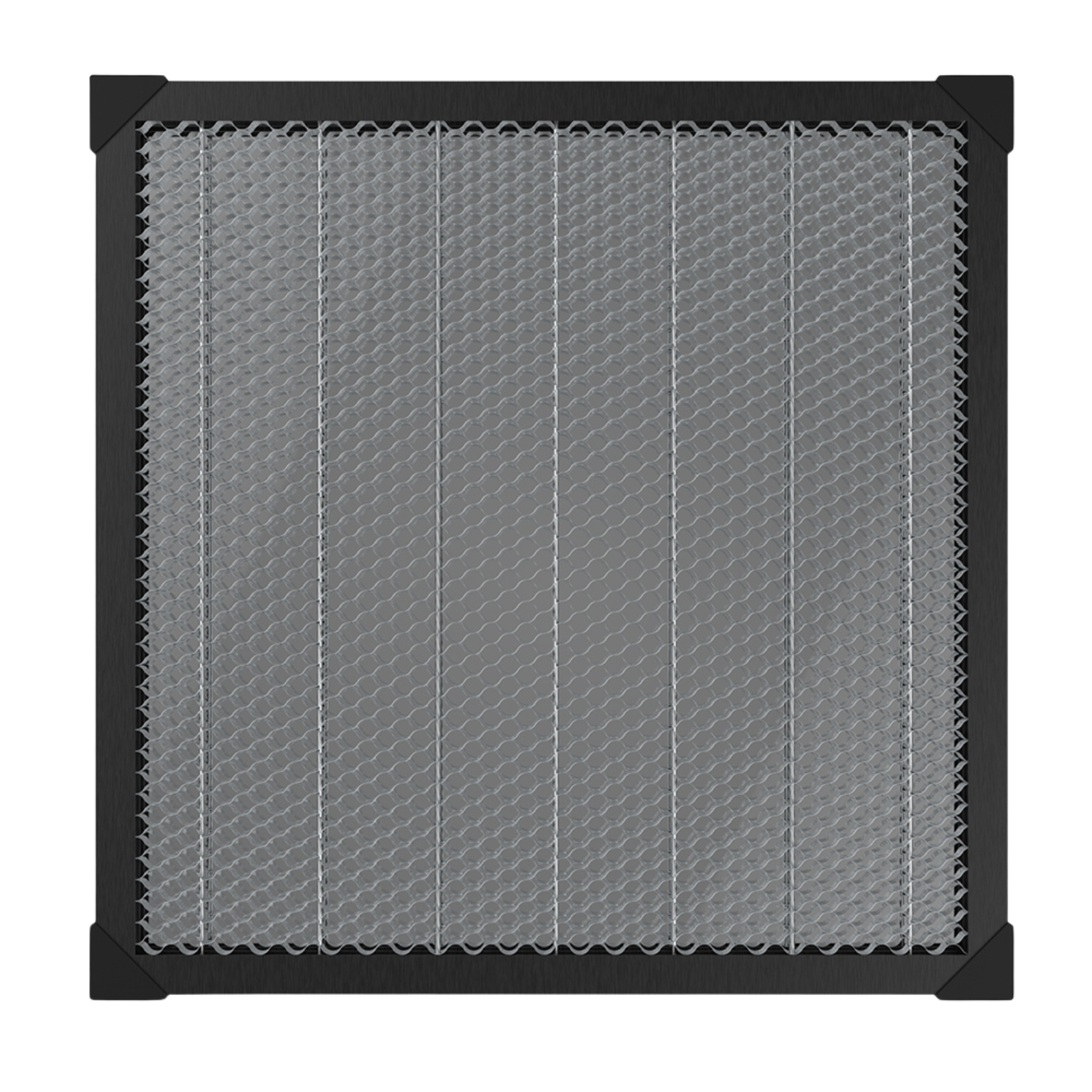

How to avoid burn marks when laser engraving wood?

To avoid burn marks, adjust the power and speed settings to optimal levels. Use a honeycomb panel laser bed for better heat dissipation. Implement an air assist to blow away smoke and reduce temperatures. Applying laser engraving masking tape can also help isolate the wood from smoke. Pre-wetting the wood can further reduce excessive heat and prevent burn marks.

What is the minimum laser power to engrave wood?

A 10W laser is sufficient to engrave wood effectively. Models like the Creality Falcon 2 40W and Falcon 2 Pro laser cutter can easily handle wood engraving tasks.